Assembly mold for a dreadnought guitar

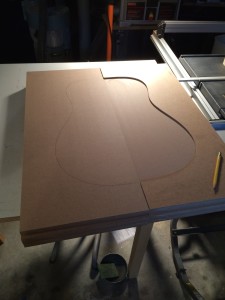

First I take a guitar that I like and trace an outline.

Next band saw a template, sand to make a fair curve and lay out in 3/4 inch MDF.

Rough cut close to the line.

Using my biggest pattern bit, I set up on a home made router table. I made an extension arm that holds a vacuum hose, well worth the effort. Not only safer, but cleaner. MDF (medium density fiber board) can make a real mess.

Next glue up 3 layers for each side, making a sandwich that measures 2 1/4 inch.

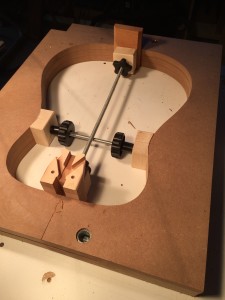

Drilling holes that will receive 3/4 inch sleeves. the sleeves are then tapped and 3/8 threaded bar is screwed in. This will make pivot point where the form is held together, making it easy open and close the form.

The corner is notched out and the a slot is made on the under side,(using a dado blade) allowing the mechanism to sit inside.

Using more 3/8 bar and a bunch of knobs I bought from wood workers warehouse, I make spreaders that will hold the the head block, tail block and sides in place.

Here the form is shown with the head stock,tail stock and sides in place.

Left is an older form, kinda flimsy and not very accurate.

The form can now be used vertically or horizontally.

Leave a Reply